India's Semiconductor Mission Takes Shape

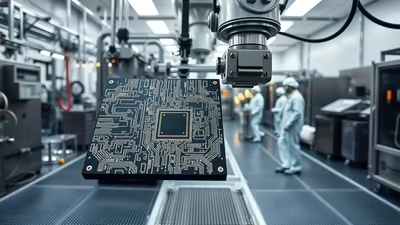

In a landmark development for India's technology sector, Tata Group has commenced construction on a massive ₹91,000 crore semiconductor fabrication plant in Gujarat. This ambitious project, part of the government's ambitious Semiconductor Mission, represents India's bold entry into the global semiconductor manufacturing landscape. The facility, expected to produce chips using advanced 28nm technology, is poised to reduce India's dependence on imports and position the country as a key player in the semiconductor supply chain.

The announcement comes at a critical juncture when global semiconductor shortages have exposed vulnerabilities in supply chains worldwide. With the COVID-19 pandemic and geopolitical tensions disrupting chip production, countries are racing to build domestic manufacturing capabilities. India's initiative, backed by substantial government incentives and private investment, aims to create a self-reliant semiconductor ecosystem that can meet both domestic demand and export opportunities.

The Tata Electronics and Semiconductor (TES) facility will be located in the Dholera Special Investment Region (SIR) in Gujarat, a strategic location chosen for its proximity to major ports, availability of skilled workforce, and supportive infrastructure. The plant will span over 1,000 acres and is expected to create thousands of high-tech jobs, contributing significantly to Gujarat's economy and India's technological advancement.

As construction begins, industry experts are watching closely as this project could be a game-changer for India's electronics manufacturing sector. The facility's 28nm technology, while not the most cutting-edge globally, represents a crucial first step in building India's semiconductor capabilities. It will enable the production of chips for smartphones, automotive applications, and consumer electronics, addressing the growing demand in these sectors.

"This is not just about building a fab; it's about building India's future in semiconductor technology. The Tata fab will be the cornerstone of our domestic semiconductor ecosystem."

— Natarajan Chandrasekaran, Chairman, Tata Sons

Tata's Strategic Entry into Semiconductor Manufacturing

Tata Group's decision to invest ₹91,000 crore in semiconductor manufacturing marks a significant expansion of its technology portfolio. The conglomerate, already a major player in IT services, automotive, and steel, is diversifying into chip manufacturing to capitalize on the growing demand for semiconductors. The project is a joint venture between Tata Electronics and Taiwan Semiconductor Manufacturing Company (TSMC), bringing world-class expertise to India's shores.

The collaboration with TSMC is particularly noteworthy. TSMC, the world's largest contract chipmaker, will provide technical know-how, equipment, and process technology for the Gujarat facility. This partnership ensures that the Tata fab will adhere to global standards from day one, producing chips that can compete in international markets. The agreement also includes technology transfer, which will help build local expertise and capabilities over time.

Tata's entry into semiconductors is part of a broader strategy to position itself as a leader in emerging technologies. The company has been investing heavily in digital transformation, AI, and IoT, and semiconductor manufacturing fits perfectly into this vision. By controlling the chip supply chain, Tata aims to provide end-to-end solutions to its customers, from design to manufacturing.

The project has received strong support from the Indian government, which has approved production-linked incentives (PLIs) worth billions of rupees. These incentives, part of the Semiconductor Mission launched in 2021, are designed to attract investments and create a favorable ecosystem for semiconductor manufacturing in India. The Tata fab is expected to benefit from these schemes, making it economically viable despite the high capital costs involved.

Gujarat: The Ideal Location for Semiconductor Hub

Gujarat's Dholera SIR has been chosen as the site for India's first large-scale semiconductor fab for several compelling reasons. The region offers excellent connectivity, with proximity to major ports like Mundra and Kandla, facilitating the import of equipment and export of finished products. The state's investment in infrastructure, including dedicated power supply and water treatment facilities, makes it an attractive destination for high-tech manufacturing.

The Gujarat government has been proactive in supporting the semiconductor initiative. Chief Minister Bhupendra Patel has announced special packages for the Tata project, including land acquisition, tax incentives, and infrastructure development. The state has also committed to providing a skilled workforce through partnerships with educational institutions and vocational training programs.

Dholera's location in the Delhi-Mumbai Industrial Corridor (DMIC) provides additional advantages. The corridor, spanning 1,483 km, is designed to boost industrial growth and create employment opportunities. The Tata fab will be part of a larger ecosystem that includes supporting industries, research institutions, and logistics hubs, creating a semiconductor cluster that can attract further investments.

Environmental considerations have also been factored into the project planning. The facility will incorporate green technologies, including water recycling systems and renewable energy sources, to minimize its environmental footprint. This approach aligns with Gujarat's focus on sustainable development and Tata's commitment to responsible manufacturing.

Advanced 28nm Technology: A Strategic Choice

The choice of 28nm technology for the Tata fab is a calculated decision that balances technological capability with market demand. While leading-edge fabs operate at 3nm or 5nm nodes, 28nm technology remains highly relevant for a wide range of applications. It is used in power management chips, display drivers, and various consumer electronics, where cost-effectiveness and reliability are paramount.

The 28nm process offers several advantages for India's entry into semiconductor manufacturing. It requires less sophisticated equipment compared to advanced nodes, reducing initial capital costs. The technology is mature, with established supply chains and design tools readily available. This makes it easier for Indian engineers and designers to adopt and innovate upon.

Moreover, the global demand for 28nm chips remains strong. With the proliferation of IoT devices, electric vehicles, and 5G infrastructure, there is a growing need for semiconductors that can handle power efficiency and performance requirements. The Tata fab will be well-positioned to serve these markets, both domestically and internationally.

The project also includes plans for technology upgrades. As the facility matures, it could transition to more advanced nodes, building on the foundation established with 28nm production. This roadmap ensures long-term viability and positions India to participate in the evolution of semiconductor technology.

Economic Impact and Job Creation

The Tata semiconductor fab is expected to have a transformative impact on India's economy. With an investment of ₹91,000 crore, it represents one of the largest foreign direct investments in the country. The project will generate direct employment for over 10,000 people, including engineers, technicians, and support staff. Indirect employment, through the supply chain and supporting industries, could add tens of thousands more jobs.

The economic benefits extend beyond job creation. The fab will reduce India's semiconductor import bill, which currently stands at over $20 billion annually. By producing chips domestically, India can save foreign exchange and boost its trade balance. The facility is also expected to generate significant export revenue, contributing to India's goal of increasing electronics exports to $300 billion by 2026.

The project will stimulate the growth of ancillary industries, including equipment manufacturing, chemical suppliers, and software development. This could lead to the creation of a comprehensive semiconductor ecosystem in India, attracting further investments from global players. The ripple effects on education and research are also significant, with increased funding for STEM education and semiconductor research.

Gujarat stands to benefit immensely from the project. The state, already a manufacturing hub, will see increased FDI and infrastructure development. The Tata fab could serve as a catalyst for other high-tech investments, positioning Gujarat as India's semiconductor capital.

Challenges and Road Ahead

Despite the optimism surrounding the Tata fab, the project faces several challenges. Building a semiconductor facility from scratch requires overcoming technical, logistical, and regulatory hurdles. Ensuring a stable power supply, water availability, and skilled workforce are critical for successful operations. The global semiconductor industry is also highly competitive, with established players in Taiwan, South Korea, and China dominating the market.

Geopolitical tensions and supply chain disruptions pose additional risks. The industry's reliance on imported equipment and materials could be affected by international relations. India will need to build strategic partnerships and diversify its supply sources to mitigate these risks.

Talent acquisition is another major challenge. The semiconductor industry requires highly specialized skills in areas like process engineering, device physics, and clean room operations. India has a shortage of such professionals, necessitating significant investments in education and training. The Tata project includes plans for skill development programs, but scaling up the workforce will take time.

Regulatory and policy challenges also exist. While the government has introduced supportive measures, implementation and coordination across different agencies will be crucial. Intellectual property protection, export controls, and technology transfer agreements need careful management to ensure the project's success.

Future Prospects and Global Implications

The Tata semiconductor fab is more than just an industrial project; it represents India's ambition to become a global player in semiconductor manufacturing. As the facility comes online, expected by 2026, it will mark the beginning of India's journey towards semiconductor self-sufficiency. The project could inspire similar investments, creating a cluster of fabs across the country.

Globally, India's entry into semiconductor manufacturing could reshape supply chains. With increasing emphasis on diversification and resilience, companies may look to India as an alternative to existing hubs. This could lead to new partnerships, technology transfers, and market opportunities for Indian firms.

The project also has implications for India's technology ecosystem. By producing chips domestically, Indian companies can design products with shorter development cycles and better integration. This could boost innovation in areas like electric vehicles, renewable energy, and digital infrastructure.

Looking ahead, the Tata fab could be the first of many. The government has set a target of attracting $10 billion in semiconductor investments by 2026. If successful, India could emerge as a significant player in the global semiconductor industry, contributing to technological advancement and economic growth.

As construction progresses at the Gujarat facility, the world watches with interest. This project symbolizes India's determination to overcome technological barriers and build a prosperous future. The semiconductor mission, with Tata leading the charge, could well be the spark that ignites India's transformation into a global technology powerhouse.